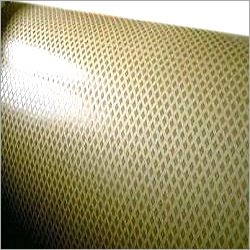

Electrical Insulating Crepe Paper

285 INR/Kilograms

Product Details:

- Paper Type Crepe Paper

- Pulp Material 100% pure cellulose

- Pulp Type Wood pulp

- Style Creped Surface

- Size Customized, standard roll widths: 20mm to 1000mm

- Thickness 0.08 mm to 0.5 mm

- Weight Ranges typically from 50gsm to 130gsm

- Click to View more

X

Electrical Insulating Crepe Paper Price And Quantity

- 285 INR/Kilograms

- 100 Kilograms

- Dry, cool, dust-free environment

- 2% at 100C

- Rolls, moisture-proof wrapping

- IEC 60554, IS: 9335

- Up to 300% (depending on grade)

- High tensile strength suitable for electrical insulation

- 6.5 8.5

- Above 10 kV/mm

- 0.6%

Electrical Insulating Crepe Paper Product Specifications

- Electrical insulation, High mechanical strength, Flexible

- Gram per cubic centimeter(g/cm3)

- Crepe Paper

- No coating

- High bursting strength

- 100% pure cellulose

- Transformer insulation, Cable isolation, Electrical component wrapping

- 0.08 mm to 0.5 mm

- 7%

- Light Brown/Natural

- No printing compatibility

- Customized, standard roll widths: 20mm to 1000mm

- Wood pulp

- Yes

- Creped Surface

- Ranges typically from 50gsm to 130gsm

- Roll

- As per requirement, up to 1000 mm

- Uniform tightness

- Uncoated

- Dry, cool, dust-free environment

- 2% at 100C

- Rolls, moisture-proof wrapping

- IEC 60554, IS: 9335

- Up to 300% (depending on grade)

- High tensile strength suitable for electrical insulation

- 6.5 8.5

- Above 10 kV/mm

- 0.6%

Electrical Insulating Crepe Paper Trade Information

- 1000 Kilograms Per Day

- 1 Week

- Yes

- Contact us for information regarding our sample policy

- All India

Product Description

As the professionally driven distributor and supplier, we are involved in providing a qualitative range of Electrical Insulating Crepe Paper. Our offered paper is one of the most durable insulation paper that are used in transformers. The provided paper is made under the strict guidance of our vendors using premium quality materials. In addition to this, we are providing this Electrical Insulating Crepe Paper to our customers in various sizes and finishes at the lowest rates.

Specification

| Material | Wood Pulp |

| Thickness | 0.5-1mm |

| Application | Adhesive Tape |

| Weight | 100-110GSM |

| Color | Brown |

| Feature | Antistatic, Greaseproof |

| Pulp Material | Wood Pulp |

Superior Electrical Insulation Performance

Electrical Insulating Crepe Paper is crafted to meet rigorous standards, offering exceptional dielectric strength exceeding 10 kV/mm and maintaining low shrinkage at high temperatures. Its remarkable elongation capacity and mechanical flexibility ensure resilience during installation and operation, making it a preferred choice for high-voltage transformer and cable insulation.

Customization and Quality Assurance

Clients benefit from tailored solutions, as crepe paper is available in a range of thicknesses, widths, and weights. The use of premium-grade wood pulp and strict adherence to international standards ensure consistent quality, tightness, and purity. This allows for hassle-free installation in various electrical insulation applications without concerns about contamination or mechanical failure.

Safe Handling and Storage Recommendations

To preserve product integrity, Electrical Insulating Crepe Paper should be stored in dry, cool, and dust-free environments. Rolls arrive with moisture-proof packaging to prevent any degradation. Proper storage and maintenance guarantee optimal electric and mechanical properties for safe and reliable use in critical electrical systems.

FAQs of Electrical Insulating Crepe Paper:

Q: How is Electrical Insulating Crepe Paper used in transformer insulation and cable isolation?

A: Electrical Insulating Crepe Paper is typically wrapped around coils, cables, and electrical components within transformers and other high-voltage equipment. Its flexibility and substantial elongation support snug fitting, while high dielectric and mechanical strengths safeguard against electrical faults and physical stress.Q: What are the main benefits of using this crepe paper for electrical insulation applications?

A: The key advantages include superior dielectric strength, customized sizing, high mechanical and bursting strength, low ash content, and excellent flexibility. These features collectively ensure effective insulation, durability, and safety in electrical installations.Q: Where and when should Electrical Insulating Crepe Paper be stored to maintain its properties?

A: The paper must be kept in dry, cool, and dust-free environments, ideally immediately after delivery in its moisture-proof packaging. Consistent conditions prevent moisture uptake and maintain the papers insulation and mechanical characteristics.Q: What process is followed to customize sizes and thicknesses of crepe paper rolls?

A: Customization involves precision cutting and creping based on the clients specifications regarding width (up to 1000mm), thickness (0.080.5mm), and GSM (50130). Orders are processed according to requirements outlined for specific electrical insulation uses.Q: How does the products high elongation affect its application in electrical systems?

A: The high elongationup to 300% depending on grademeans the paper can withstand significant stretching without breaking, ensuring close adherence to surfaces, better coverage, and reduced risk of tears during installation and operation.Q: Can Electrical Insulating Crepe Paper be used for printing or labeling within electrical applications?

A: No, this type of crepe paper is not compatible with printing processes. Its primary function is electrical insulation, and its uncoated, pure cellulose surface is optimized exclusively for electrical wrapping rather than printing.Q: What standards does this crepe paper comply with, and why are they important?

A: Electrical Insulating Crepe Paper meets IEC 60554 and IS:9335 standards, critical for ensuring consistent electrical safety, integrity, and performance in professional installations worldwide. Adhering to these standards guarantees suitability for demanding electrical insulation environments.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry