Call: 08045812793

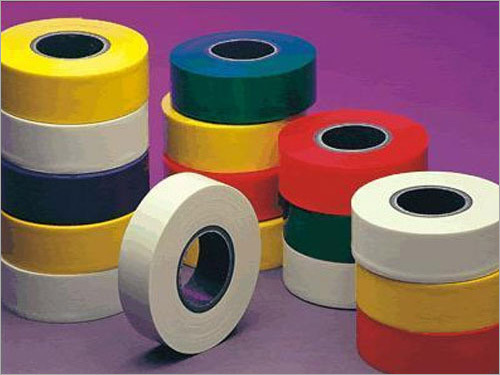

Electrical Adhesive Tapes

9 INR/Roll

Product Details:

- Thickness 0.13 mm

- Peeling Strength Good adhesion with strong peeling strength

- Adhesive Side Single Side

- Shelf Life 12 months

- Elongation 130%

- Length 7 m

- Tape Type Single Sided

- Click to View more

X

Electrical Adhesive Tapes Price And Quantity

- 9 INR/Roll

- 1 Roll

- 20 N/10mm

- Yes

- Up to 80°C

- Yes

- 600V

- Wires, Cables, Insulation Wrap

Electrical Adhesive Tapes Product Specifications

- 19 mm

- Single Sided

- 0.13 mm

- Electrical Insulation

- 7 m

- 0.13 mm

- Good adhesion with strong peeling strength

- PVC (Polyvinyl Chloride)

- Acrylic

- Single Side

- 12 months

- 7 m

- Yellow and Green

- 130%

- 20 N/10mm

- Yes

- Up to 80°C

- Yes

- 600V

- Wires, Cables, Insulation Wrap

Electrical Adhesive Tapes Trade Information

- 1000 Roll Per Day

- 1 Week

- Yes

- Contact us for information regarding our sample policy

- Australia, North America, Middle East, Western Europe, Africa, Central America, South America, Asia, Eastern Europe

- All India

Product Description

At our updated production facility, we are able to provide superior quality Electrically Conductive Tapes. These tapes are able to withstand high temperatures in the industry. It is manufactured by making use of PVC, acrylic compounds and latest technology under the stern supervision of our dexterous team of professionals. The offered tape is widely used in electrical industry. Tested on several quality parameters before delivering, this Electrically Conductive Tape can be availed from us at market leading prices.

Exceptional Durability and Safety

Engineered from premium PVC and equipped with acrylic adhesive, this tape guarantees robust performance under stress. Its flame retardant and water-resistant properties enhance safety, especially in electrical applications. The tape maintains strong adhesion and optimal elasticity, ensuring secure wrapping and insulation that resists environmental fluctuations. With a shelf life of 12 months, its a dependable choice for long-term electrical projects.

Versatile Applications for Electrical Projects

Designed to meet the demands of professionals, this tape is suitable for a range of surfaces including wires, cables, and insulation wraps. Its vivid yellow and green color aid quick circuit identification, minimizing installation errors. Whether in residential, commercial, or industrial settings, this tapes exceptional mechanical and electrical characteristics make it a preferred solution for insulation and safety.

FAQs of Electrical Adhesive Tapes:

Q: How should I apply this electrical tape for optimal insulation?

A: To achieve effective insulation, clean and dry the surface of wires or cables before wrapping. Stretch the tape slightly as you wind it around the object, overlapping half the width. Press firmly to ensure solid adhesion given its strong peeling strength. This method provides maximum protection and longevity.Q: What makes this electrical adhesive tape flame retardant and water resistant?

A: The tape is crafted from PVC material with specialized flame-retardant properties, ensuring safety in high-risk environments. Additionally, its water-resistant design prevents moisture ingress, safeguarding connections against damage and corrosion in damp conditions.Q: When should I replace the tape on existing electrical connections?

A: You should inspect taped connections periodically and replace the tape if it shows signs of wear, loss of adhesion, or after the 12-month shelf life. Early replacement is also recommended if exposed to conditions exceeding the specified temperature (80C) or voltage (600V) limits.Q: Where is this tape most suitable for use?

A: This tape is best used on wires, cables, and insulation wraps in electrical installations, both indoors and outdoors within its rated limits. The yellow and green color makes it ideal for grounding applications and easy identification in electrical panels or junction boxes.Q: What are the benefits of using this tape over standard insulation options?

A: Compared to standard tapes, it offers superior adhesion, tensile strength, and elongation, adapting well to irregular surfaces and wire bends. Its flame retardant and water-resistant features provide enhanced safety, while its robust PVC construction assures long-lasting performance.Q: How does the tapes acrylic adhesive contribute to performance?

A: The acrylic adhesive delivers reliable bonding, even under mechanical stress and temperature fluctuations, ensuring the tape stays securely in place. This maintains electrical insulation integrity, minimizing the risk of short circuits or exposed wires.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry